Main Applications

Mainly used at locations of piping for the passage of fuel (liquid, gas) for automobiles. Extrusion molding of straight and corrugated shapes, and delivery of assemblies with fittings into tubes, are also possible.

layer

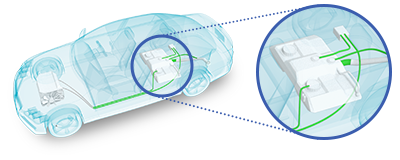

■ in fuel pump modules

■ in-tank use

■ areas around engines

*Only tubes with heat resistance

layer

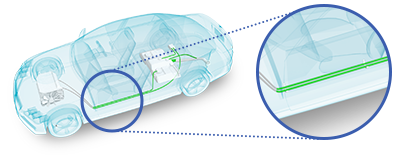

■ fuel tank main (feed) piping from fuel tank

■ underfloor piping

FeaturesFEATURES

Mass can be reduced in comparison to metal and rubber hoses, contributing to improved automobile fuel efficiency.

environmental regulations

These products have excellent properties for low permeability of gasoline, and comply with the evaporative control regulations of various countries.

Applicable regulations:

LEV III (USA), CHINA 6 (China), EURO6 (Europe), BS6 (India), etc.

layout design

Since the tubes have thermoplastic properties, they can be bent easily.

Basic Product InformationRequest for documentation

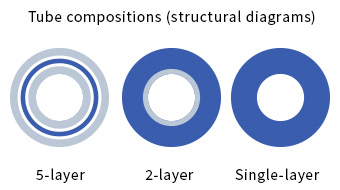

These are thermoplastic tubes made primarily of nylon (polyamide) based material. Aside from standard specifications, we can also respond to match requested sizes, shapes, and properties.

| Single-layer | Multi-layer | |

|---|---|---|

| Supported Materials |

Nylon (polyamide) based | PBN, ETFE, EVOH, etc. |

| Tube Diameter |

Maximum diameter: outer diameter of roughly φ40 Minimum diameter: can be designed according to consultations |

Maximum diameter: outer diameter of roughly φ40 Minimum diameter: can be designed according to consultations |

| Shapes | Straight shapes Corrugated shapes |

Straight shapes Corrugated shapes |

| Properties | Heat resistance *Pressure resistance, pull-out resistance, permeation resistance, etc. can also be supported. |

Conductivity Low oligomer properties Low permeability |

Application Proposals

Can be used in applications for vaporized gasoline (vapor) and liquid gasoline (feed) in areas around fuel tanks.

■ Conductivity, low oligomer properties

*Depending on the material

Can be used in applications for vapor piping of underfloor collective piping.

■ Cost reduction

Results of Use

around fuel tanks

We have numerous results of use of thermoplastic tubes in areas around fuel tanks for various automobile manufacturers.

by all automobile manufacturers

We have results of use by all automobile manufacturers, through pump module manufacturers.

Note that the above are only selected examples, and we are able to produce piping to meet customer needs.

We have many other results of use as well, so please feel free to inquire with us for more information.

Nitta’s Technology

Can be molded into shapes that meet customer requests. Can even be applied in difficult pipe arrangements, providing more design freedom.

Since our thermoplastic tubes are extrusion molded with high dimensional accuracy, variations in performance between and within production lots are controlled.

We possess various types of evaluation equipment in addition to SHED (“Sealed Housing for Evaporative Determination” equipment for measuring fuel evaporative gases). We can carry out various types of quality verification internally, allowing us to provide even earlier support for evaluations.

We possess technology to accurately perform extrusion molding on melted thermoplastic to form tube shapes. Fine adjustments of tube inner and outer diameters, and adjustment of wall thicknesses, are also possible.

Tubes can be formed (bent) and processed into desired piping shapes. Since the accuracy of these bending processes is high, they can be useful to eliminate interference during assembly, so our tubes can be applied to routing in narrow spaces.

technology

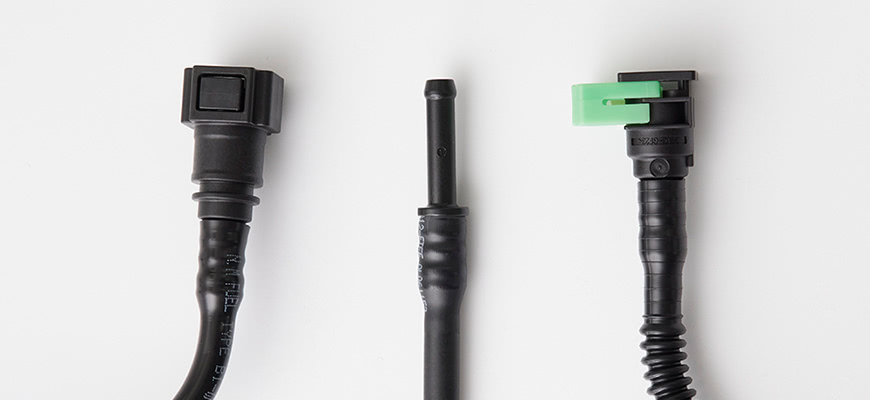

We can offer processing techniques such as press-fitting connectors (joints) to both ends of tubes, attaching protectors to tubes, and installing clips.

(proposafor connector attachment, etc.)

We can use connectors (joints) and other components to propose connection methods suitable for customer applications.

Inquiries

Feel free to contact us if you wish to request documentation,

have questions about products, or are seeking consultation.

the Inquiry Form

For inquiries by telephone

Auto Sales Department, Nitta Moore Division, Nitta Corporation

Support hours: 9:00 - 17:30 on weekdays

(not available on weekends and holidays)