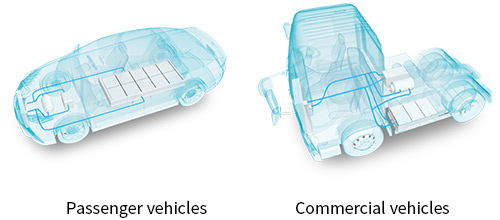

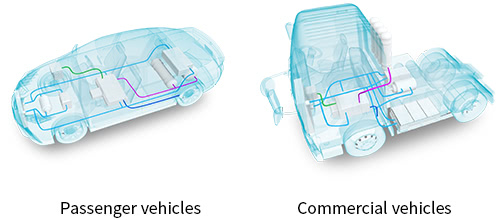

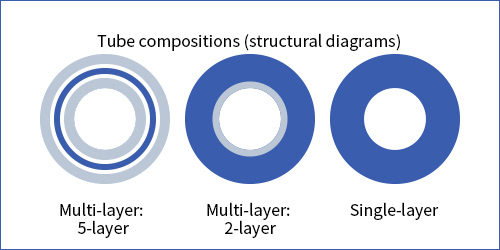

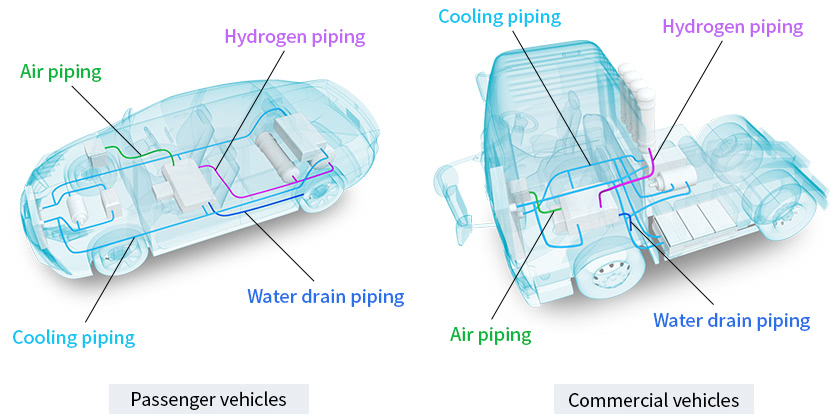

Thermoplastic tubes are products made of thermoplastic thermoplastic molded into the shape of tubes. They have the advantage of being relatively lightweight and easy to process, and play important roles in transporting gases and fluids or transmitting pressure. Their quality and performance allow them to be used in automotive applications, and they can also contribute to carbon neutrality depending on their material.

Nitta’s thermoplastic tubes can

satisfy the needs of

various manufacturers in

the automotive industry.

material numbers

We can create prototypes according to your requests.