Just like a human hand,gently

"hold", "pinch", "pick up"

Robot hand for soft handling

Robot hand SOFTmatics™ uses an original gripping mechanism

to gently pick up and hold irregularly

shaped, mixed, or breakable objects.

Do you have any of

these problems?

We have to do it by hand…

But we can't afford that much manpower…

to handle due

to variation

in size…

to hold them due

to the irregular

shape…

workpiece…

in the

pick-and-place

…

A Gentle Solution to Your Worker Shortage Issue

Support conveyance automation with SOFTmatics™.

NITTA's “SOFTmatics™” can gently hold, pick up, and pinch the workpiece in place of the human hand for irregular shapes, mixed, or breakable objects.

Robot hand for soft handling

Features of SOFTmatics™

The 5 key points of SOFTmatics™.

Can hold workpieces that could not be held before

A unique gripping mechanism* enables smooth movement.Flexible urethane material allows for gentle handling without damage to delicate workpieces.*

Hygienic gripper allows for direct handling of foods

DiversityUses materials that comply with the Food Sanitation Act*

Also, it has no indentations or recesses, making it suitable for wipe/rinse cleaning.

* Ministry of Health and Welfare Notification No. 370 (as of May 2021)

* Gripper body part complies with FDA 21 CFR 177.2600 dissolution test (as of April 2023)

installation

Tool-less detachable mechanism for easy maintenance

No risk of screws falling when attaching/detaching, and work time is greatly reduced when cleaning or in changing stages.

weight

Made of aluminum and total weight 1.0 kg or less *

Made of aluminum and total weight 1.0 kg or less *

* Excluding adapter plate.

Perishable parts are repairable

Grippers can be repaired (fee required).

* Please contact us for information about repairable parts.

Robot hand for soft handling

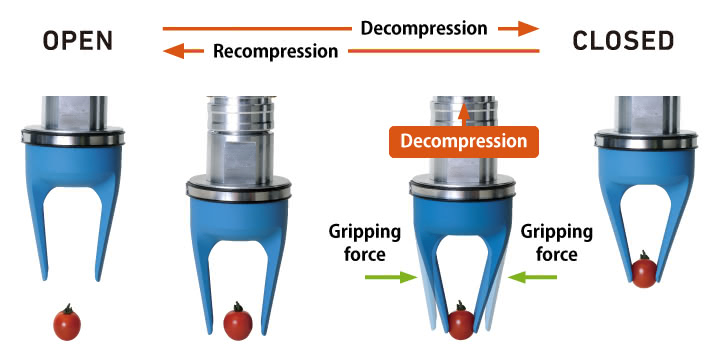

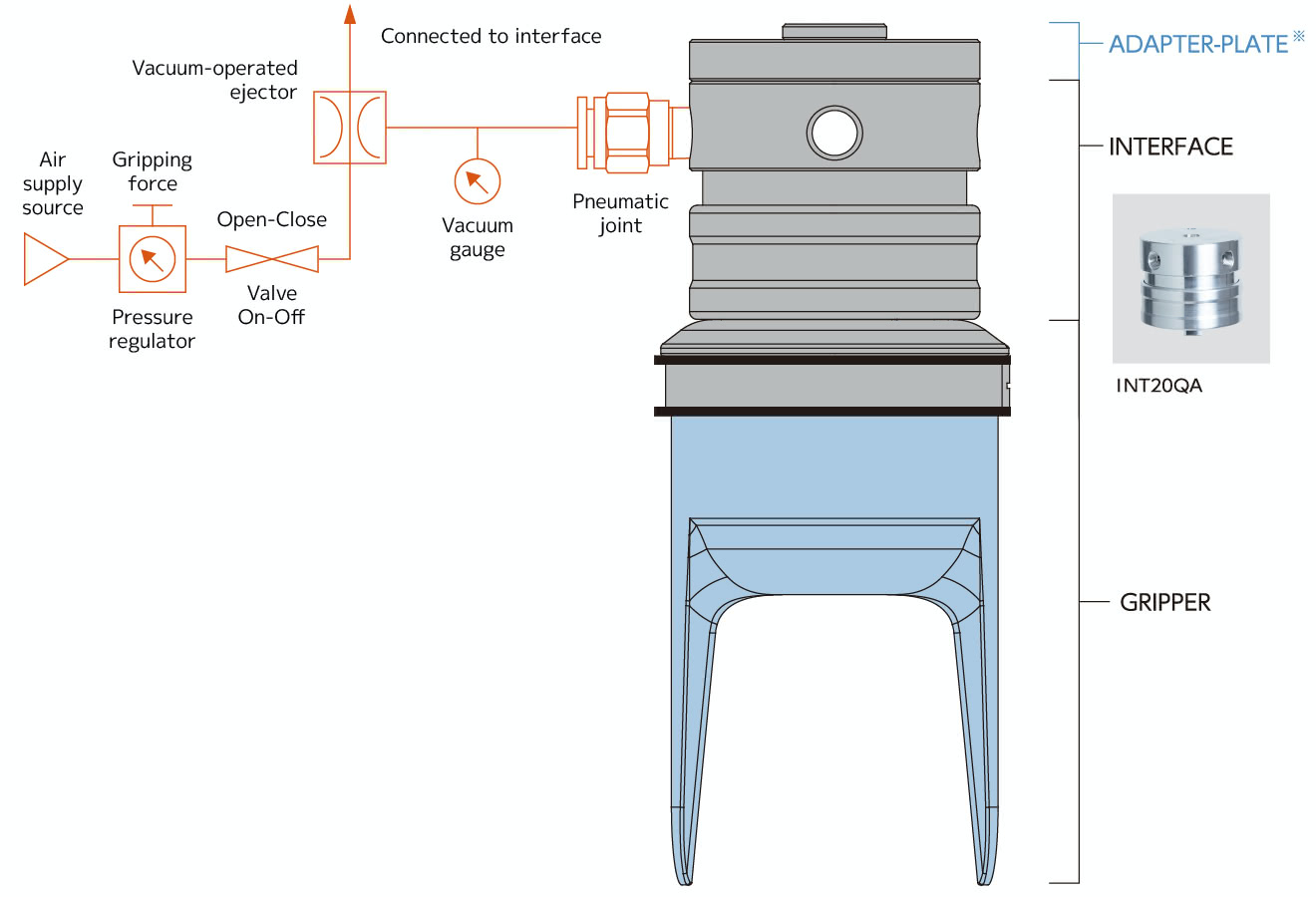

Operating principle of SOFTmatics™

Decompressing the inside of the hand works the gripper.

By recompressing, the gripper returns to the open state.

Original design of

simple gripping mechanism

- Gripper is driven by decompression force

- Turn the air circuit On or OFF to open or close.

- Gripping force can be changed by stepless

adjustment of pressure!

Robot hand for soft handling

Examples of SOFTmatics™ in use.

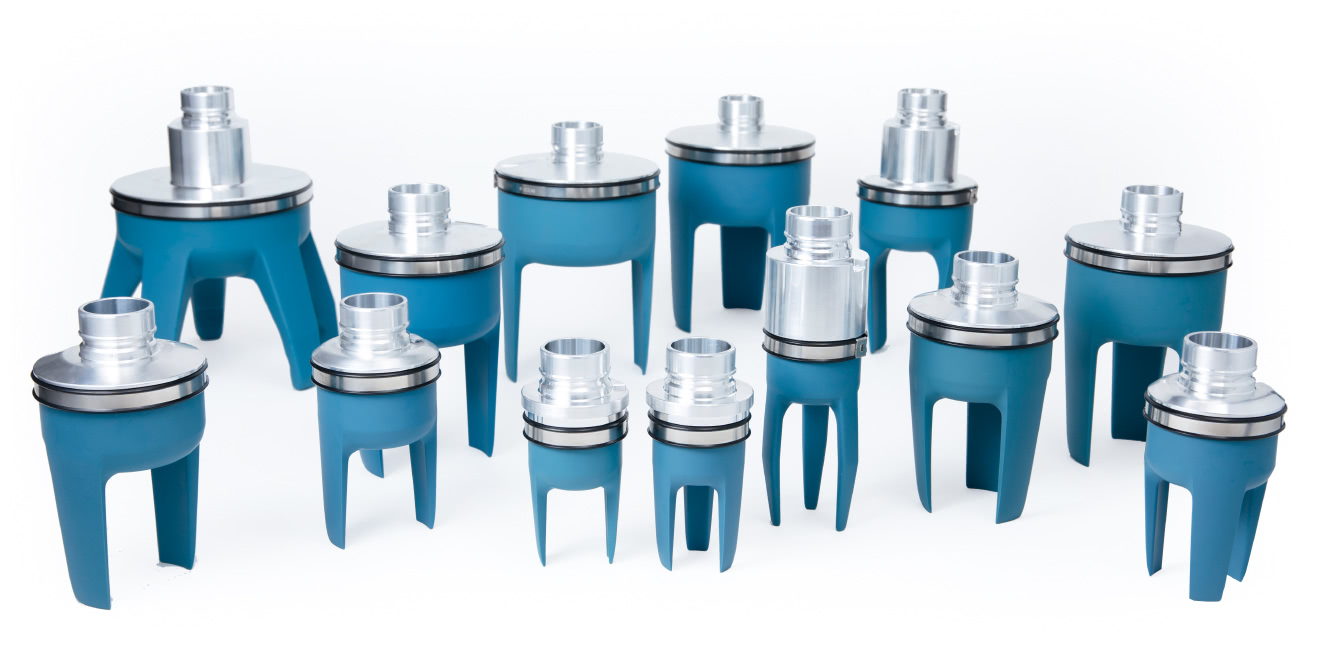

Gripper shape to suit workpieces from small to large

Grippers with different sizes and finger shapes can be used to 'Hold', 'Pick up' and 'pinch'.

Available in a range of sizes and shapes to best suit the workpiece.

with video

Visit here for video of gripping operation.

Robot hand for soft handling

Applications of SOFTmatics™

Realization of tasks previously difficult to automate

Grippers of different sizes and finger shapes can be used for "hold", "pinch" and "pick up".

The line-up is available in a variety of sizes and shapes to best suit the workpiece.

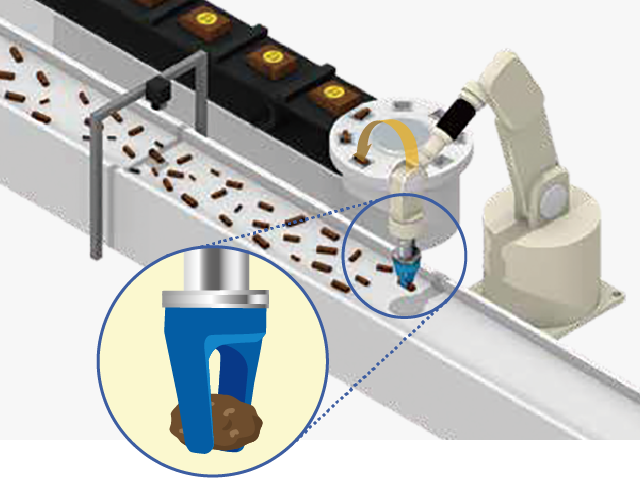

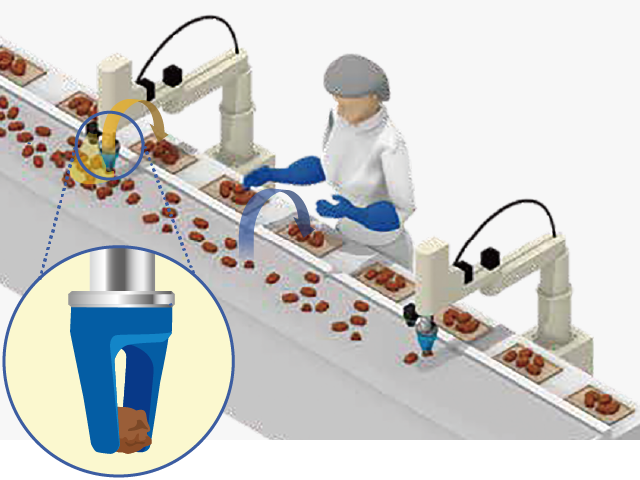

Feeding to packaging machine/weighing scales

The robot picks up workpieces on the conveyor that are recognized by vision and feeds them to the packaging machine. Use of SOFTmatics™ makes it possible to pick up foodstuffs of various sizes and shapes, such as chocolate.

Packing onto trays

A robot picks up foodstuffs from the conveyor and places them on trays. SOFTmatics™ uses flexible elastomer and decompression drive, making it gentle and safe for the work environment, and when used with a collaborative robot, workers can feel safe beside the robot.

* For actual operation, please be sure to conduct a risk assessment before use.

Others

Packing of products/parts in boxes

Loading/unloading workpieces into and from processing machine

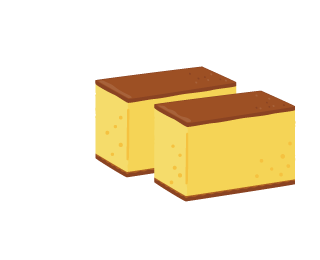

Adjust to mixed sizes of

Baumkuchen cake and increase the grip rate.

Problem

The diameter of Baumkuchen may vary slightly due to seasonal variations in ingredients and processing conditions.

Therefore, previous robot hands caused chuck errors.

Solution

The SOFTmatics™ three-jaw type adjusts to the variation in diameter and individual variability of Baum-kuchen.

Chuck errores were improved.

Effect*Calculated based on customer

feedback with human hands.

Grip rate : 95-97% → 100%

Maintenance time: Max. 4 hours/day → 0 hours/day

Picking up items is faster, more accurate, and less tiring than with human hands. One-touch attachment and detachment for easy cleaning received a favorable evaluation.

with video

Click here for applications

Robot hand for soft handling

Product structure and piping layout of SOFTmatics™

The gripper can be opened and closed simply by On-Off of the valve.

By adjusting the pressure and flow rate, the gripping force and open/close time can be adjusted respectively.

This product consists of an interface and a gripper. An adapter plate and its peripherals are required for use.

* Manufacture according to the interface and robot flange shape.

with video

Visit here for video of installation,

and pressure setting.

| Model | GR20QA -V3A |

GR20QA -DKA |

GR20QA -BMA |

GR20QA -PB2A |

GR20QA -PC2A |

GR20QA -PD2A |

GR20QA -PE2A |

GR20QA -PF2A |

GR20QA -PB3A |

GR20QA -PC3A |

GR20QA -PD3A |

GR20QA -PE3A |

GR20QA -PF3A |

INT20QA |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Weight (g)*1 |

786 | 436 | 233 | 174 | 285 | 371 | 554 | 815 | 177 | 290 | 380 | 567 | 831 | 155 |

| Reference weight capacity (g)*2 |

1380 | 400 | 200 | 120 | 210 | 260 | 320 | 390 | 80 | 250 | 330 | 330 | 460 | -- |

| Height H(mm) |

70 | 80 | 70 | 45 | 56 | 70 | 80 | 85 | 48 | 58 | 70 | 80 | 85 | -- |

| Maximum O.D. W (mm) |

178 | 87 | 60 | 56 | 70 | 85 | 100 | 115 | 56 | 70 | 85 | 100 | 115 | -- |

| Vacuum degree (-MPa) |

0.03 | 0.06 | 0.08 | 0.06 | 0.06 | 0.04 | 0.03 | 0.03 | 0.06 | 0.06 | 0.04 | 0.03 | 0.03 | -- |

| Estimated work-piece size (mm)*3 |

φ140 | φ40 | φ40 | φ20 | φ35 | φ50 | φ65 | φ80 | φ20 | φ35 | φ50 | φ65 | φ80 | -- |

| download drawings. | ||||||||||||||

| 2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

2DCAD (DXF) |

|

| 3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

3DCAD (IGS) |

The interface can be attached to all grippers. Seal washers and M8 cap bolts for installation are included.

*1 This is only the weight of the gripper.

*2 Weight capacity varies depending on the workpiece to be gripped. Please test with a demo machine for possiblity of gripping the workpiece. size that can be handled without difficulty.

*3 Estimated workpiece size indicates the size that can be handled without difficulty.

● Operating fluid : Air

● Working temperature range : 5°C ~ 45°C

● Chemical resistance: Hot water, synthetic detergent and ethanol can be used. Do not use hypochlorous acid.

An adapter plate is required for installation of the hand. Refer to the dimensional drawing of the interface and manufacture.

If the flange to be installed is ISO 9409-1, or a robot shown below, refer to the following adapter plate reference drawings.

| Adapter plate part number | Adapter plate drawing | Compatible flange shapes |

|---|---|---|

| A-ISO9409-1-2-AP | ISO9409-1-31.5-4-M5 | |

| 2DCAD(DXF) | ||

| 3DCAD(IGS) | ||

| A-ISO9409-1-4-AP | ISO9409-1-50-4-M6 | |

| 2DCAD(DXF) | ||

| 3DCAD(IGS) | ||

| A-Y0301-AP | YASKAWA Electric Corporation: MOTOMAN-HC10 |

|

| 2DCAD(DXF) | ||

| 3DCAD(IGS) | ||

| A-Y0302-AP | YASKAWA Electric Corporation: MOTOMAN-HC10DT, MOTOMAN-HC10DT (hand-carry type) |

|

| 2DCAD(DXF) | ||

| 3DCAD(IGS) | ||

| A-Y0303-AP | YASKAWA Electric Corporation: MOTOMAN-HC10DT (dust-proof and drip-proof type), MOTOMAN-HC10DTF (food type) |

|

| 2DCAD(DXF) | ||

| 3DCAD(IGS) |

* Compatible ISO: ISO9409

* The content is current as of September 2019. Standards are subject to change without notice, please be sure to check them before manufacturing.