This is the most flexible resin hose (Nitta comparison), and reduces the load during hose installation.

It also flexibly supports complex layouts with good following performance.

The Linemate™ resin hose from Nitta is used in various machinery.

Linemate™ can solve your issues!

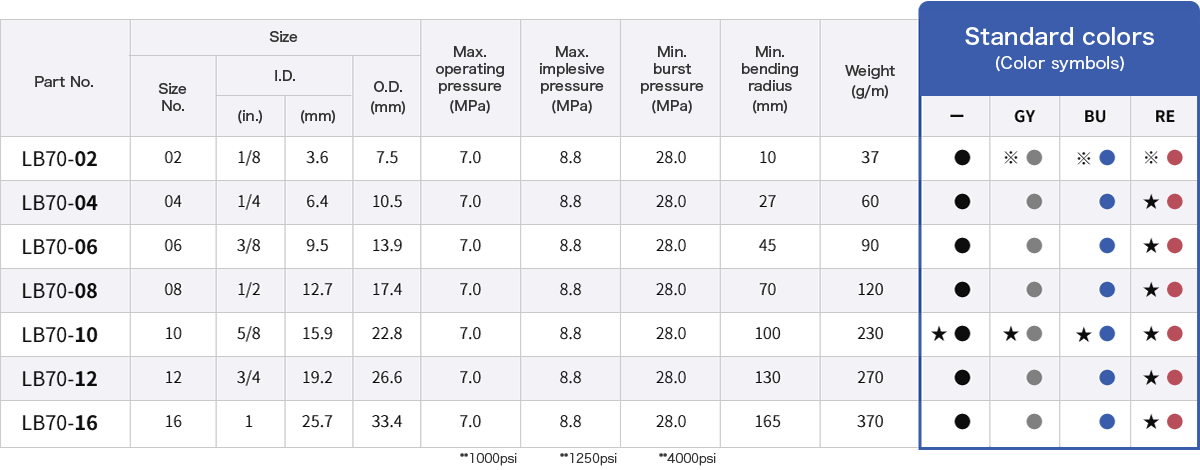

Lightweight, thin and strong

The outer diameter of the hose is smaller than that of a rubber hose with wire. This makes piping in a narrow space easy and is effective for making equipment more compact.

The mass of the hose is 1/2 to 1/4 that of a rubber hose, making it possible to reduce the weight of equipment and to save energy.

The cover material is a polyurethane cover, so it has superior wear resistance compared to rubber hose, and the frequency of hose replacement due to wear can be reduced.

Synthetic fiber is used for the reinforcement layer, so the hose is strong against repeated bending and impacts, and bending fatigue does not easily occur.

It can also be used with a smaller bending radius than a rubber hose containing wire.

The cover material can be color processed.

The new LB70 series has different color hoses in the standard lineup.

*Researched by Nitta

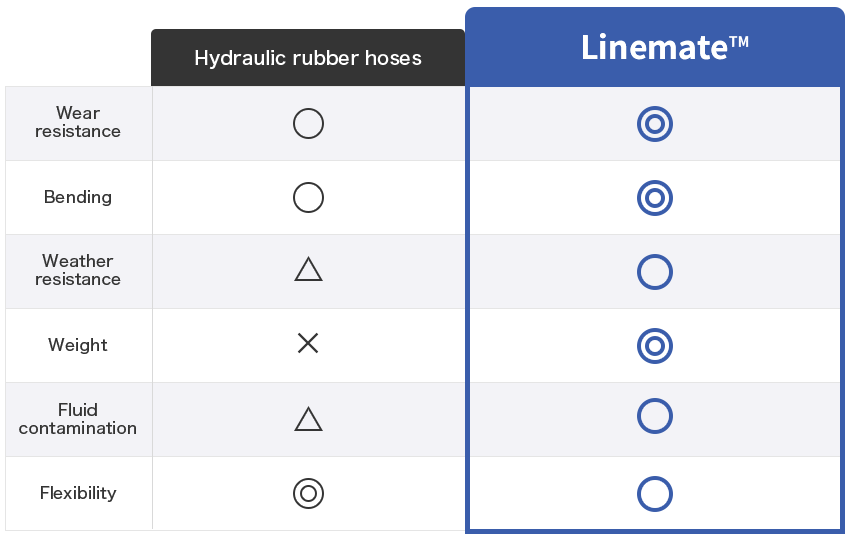

Compared with rubber hoses for hydraulics, this hose has superior wear resistance, bending,

and weather resistance, and is also lightweight and does not contaminate the fluid.

In addition, some of the hoses have fittings that can be fastened with Push-One.

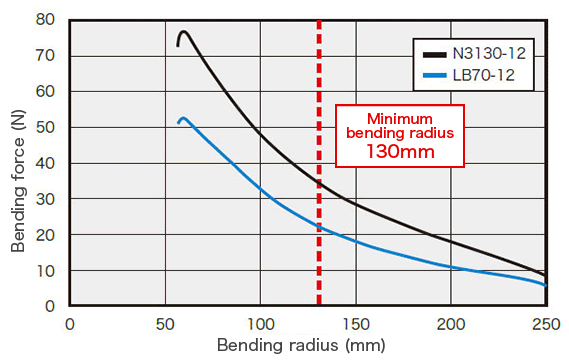

This is the most flexible resin hose (Nitta comparison), and reduces the load during hose installation.

It also flexibly supports complex layouts with good following performance.

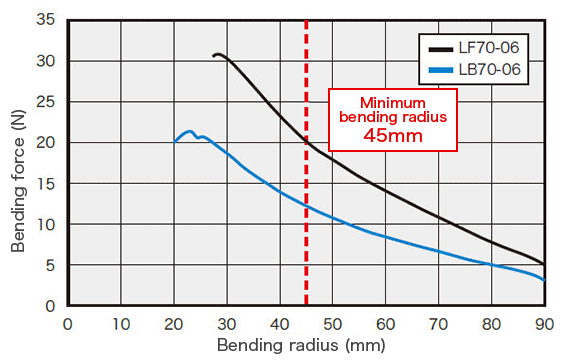

Attach a hose to a testing machine in the state where it is bent 180° and then gradually reduce the bending radius and investigate the relationship between the bending radius and bending force.

[Test conditions] Test speed: 100 mm/min, Temperature: Room temperature

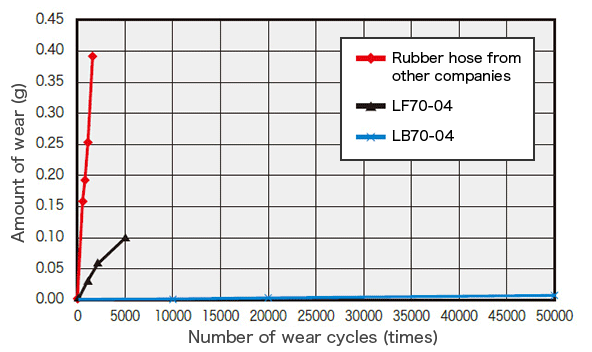

The cover material is a polyurethane cover, so it has superior wear resistance compared to rubber hose, and the frequency of hose replacement due to wear can be reduced.

Cut the hose to 150 mm, leave it in a constant temperature, constant humidity chamber for one week, and then weigh it.

Insert a fixing rod into the hose and then attach it to the bottom face of the testing machine. Attach a grindstone to the upper surface.

Complete the number of test cycles specified and then leave the hose in the constant temperature, constant humidity chamber for one week then weigh it and investigate the change between before and after the test.

[Test conditions]

Test load: 2.5 kg, Temperature: Room temperature (23°C),

Stroke: 100 mm,

Cycle: 200 times (Reciprocating)/min,

Grindstone: Taber abrasive wheel H-22 (Grain size: Approx. 60)

Hose color can be selected per fluid. Using separate colors helps prevent mistakes in installation.

*Please contact our company if you would like a color item of size 02.

★Product built-to-order

Lightweight, thin and strong

We have continued to supply products suitable for applications based on requests from various industries.

We use the extensive knowledge and outstanding technical capabilities gained through those efforts to support customers in the construction of piping systems that best meet their needs.

Two hoses can be welded together.

Using a double hose has the following effects.

It is also possible to weld three or more hoses together, and to weld a hose with a tube.

These can be attached to the entire length of the hose, to both ends of the joint, or to one end of the joint.

Attaching a guard spring has the following effects.

The material is steel.

Please stretch the product to 2 to 2.5 times the length of its tightly adhered state for use.

We also perform other hose processing and protective part attachment, etc., in response to customer requests.

If you are considering the special processing of hoses, please feel free to contact us.

| Trade Name | Nitta Corporation |

|---|---|

| Address of Headquarters | 4-4-26 Sakuragawa, Naniwa-ku, Osaka, 556-0022 Phone: +81-6-6563-1211 / FAX: +81-6-6563-1212GoogleMap |

| Founded | March 18, 1885 |

| Established | February 10, 1945 |

Nitta resin hose Linemate™ - Download a catalog!

Please feel free to contact us.

| Sales Department, Nitta Moore Division, Nitta Corporation |

|---|

| Support hours: 9:00 - 17:30 on weekdays |

| Osaka | TEL.06-6563-1271 FAX.06-6563-1272 |

|---|---|

| Tokyo | TEL.03-6744-2725 FAX.03-6744-2707 |

| Nagoya | TEL.052-589-1321 FAX.052-566-2005 |

| Fukuoka | TEL.092-473-6651 FAX.092-474-2658 |

At Nitta, we basically refer to items with a fiber reinforced layer or other to improve the pressure resistance performance as "hoses" and items with no such reinforcement as "tubes".